Raws li kev tshawb nrhiav thiab kev tshuaj xyuas, xeb yog ib qho ntawm cov yam tseem ceeb ua rau puas tsuaj rau cov npauj npaim valve. Vim tias lub qhov sab hauv sib cuag nrog cov khoom nruab nrab, nws xeb heev. Tom qab xeb, lub valve txoj kab uas hla me dua thiab qhov tsis kam ntws nce ntxiv, uas cuam tshuam rau kev sib kis ntawm cov khoom nruab nrab. Lubqhov chaw ntawm lub cev valveFeem ntau yog ntsia rau hauv av lossis hauv av. Qhov saum npoo yog sib cuag nrog huab cua thiab huab cua yog noo noo, yog li nws yooj yim xeb. Lub rooj zaum valve raug npog tag nrho qhov twg lub qhov sab hauv sib cuag nrog qhov nruab nrab. Yog li ntawd, kev kho txheej saum npoo ntawm lub cev valve thiab lub phaj valve yog txoj hauv kev tiv thaiv pheej yig tshaj plaws tiv thaiv kev xeb hauv qhov chaw sab nraud.

1. Lub luag haujlwm ntawm lub hau npog ntawm lub hau npog

01. Kev txheeb xyuas cov khoom siv ntawm lub cev valve

Cov xim ntawm cov txheej saum npoo ntawm lub cev valve thiab lub hau valve raug siv rau cov nplaim ntawm lub cev valve thiab lub hau valve uas tsis tau siv tshuab. Los ntawm cov xim cim no, peb tuaj yeem txiav txim siab sai sai txog cov khoom siv ntawm lub cev valve thiab nkag siab zoo dua txog nws cov yam ntxwv.

| Cov Khoom Siv Lub Cev Valve | Xim pleev xim | Cov Khoom Siv Lub Cev Valve | Xim pleev xim |

| Hlau cam khwb cia | Dub | Hlau Ductile | Xiav |

| Hlau Forged | Dub | WCB | Xim av |

02. Kev tiv thaiv zoo

Tom qab lub cev valve nto raug pleev xim, lub cev valve nto raug cais tawm ntawm ib puag ncig. Qhov kev tiv thaiv no tuaj yeem hu ua kev tiv thaiv. Txawm li cas los xij, nws yuav tsum tau taw qhia tias ib txheej nyias nyias ntawm cov xim tsis tuaj yeem muab qhov kev tiv thaiv tag nrho. Vim tias cov polymers muaj qee qib ntawm kev ua pa, thaum lub txheej nyias heev, cov qauv pores tso cai rau cov dej thiab cov pa oxygen hla mus dawb. Cov valve soft-sealing muaj cov kev cai nruj ntawm qhov tuab ntawm epoxy resin txheej ntawm qhov chaw. Txhawm rau txhim kho qhov tsis kam ntawm lub txheej, cov txheej tiv thaiv xeb yuav tsum siv cov tshuaj ua zaj duab xis nrog cov huab cua qis permeability thiab cov khoom khov kho nrog cov khoom tiv thaiv siab. Tib lub sijhawm, tus lej ntawm cov txheej txheej yuav tsum tau nce kom lub txheej ncav cuag qee qhov tuab thiab yog ntom thiab tsis-porous.

03. Kev tiv thaiv xeb

Cov khoom sab hauv ntawm cov xim pleev xim cuam tshuam nrog cov hlau kom ua rau cov hlau tsis muaj zog lossis tsim cov tshuaj tiv thaiv kom txhim kho cov nyhuv tiv thaiv ntawm cov txheej. Rau cov li qub uas muaj cov kev xav tau tshwj xeeb, koj yuav tsum tau them sai sai rau cov xim pleev xim kom tsis txhob muaj cov teebmeem tsis zoo. Tsis tas li ntawd, cov li qub hlau siv hauv cov kav dej roj kuj tseem tuaj yeem ua haujlwm ua cov tshuaj tiv thaiv xeb organic vim yog cov khoom puas tsuaj uas tsim los ntawm qee cov roj thiab kev ua kom qhuav ntawm cov xab npum hlau.

04. Kev tiv thaiv hluav taws xob

Thaum cov txheej dielectric nkag mus rau hauv kev sib cuag nrog cov hlau nto, electrochemical corrosion nyob rau hauv zaj duab xis yuav tsim. Cov hlau uas muaj kev ua haujlwm siab dua li hlau yog siv los ua cov khoom sau hauv cov txheej, xws li zinc. Nws yuav ua lub luag haujlwm tiv thaiv ua lub anode sacrificial, thiab cov khoom xeb ntawm zinc yog ntsev-raws li zinc chloride thiab zinc carbonate, uas yuav sau cov qhov sib txawv hauv zaj duab xis thiab ua rau zaj duab xis nruj, txo qis corrosion thiab ntev lub neej kev pabcuam ntawm lub valve.

2. Cov txheej txheem feem ntau siv rau ntawm cov hlau li qub

Cov txheej txheem kho qhov chaw ntawm cov li qub feem ntau suav nrog kev pleev xim, galvanizing thiab hmoov txheej. Lub sijhawm tiv thaiv ntawm cov xim luv luv thiab tsis tuaj yeem siv rau hauv cov xwm txheej ua haujlwm ntev. Cov txheej txheem galvanizing feem ntau yog siv rau hauv cov kav dej. Ob qho tib si kub-dip galvanizing thiab electro-galvanizing siv. Cov txheej txheem yog qhov nyuaj. Kev kho ua ntej siv cov txheej txheem pickling thiab phosphating. Yuav muaj cov kua qaub thiab alkali seem ntawm qhov chaw ua haujlwm, tawm hauv corrosion. Kev phom sij zais ua rau cov txheej galvanized yooj yim poob tawm. Kev tiv thaiv corrosion ntawm cov hlau galvanized yog 3 txog 5 xyoos. Cov hmoov txheej siv hauv peb cov li qub Zhongfa muaj cov yam ntxwv ntawm cov txheej tuab, tiv thaiv corrosion, tiv thaiv kev yaig, thiab lwm yam, uas tuaj yeem ua tau raws li qhov xav tau ntawm cov li qub nyob rau hauv cov xwm txheej siv ntawm lub kaw lus dej.

01. Lub cev valve epoxy resin txheej

Muaj cov yam ntxwv hauv qab no:

· Kev tiv thaiv xeb: Cov hlau uas muaj epoxy resin-coated muaj kev tiv thaiv xeb zoo, thiab lub zog sib txuas nrog cov pob zeb ua vaj tse raug txo qis heev. Lawv tsim nyog rau cov xwm txheej kev lag luam hauv cov chaw noo noo lossis cov xov xwm corrosive.

· Kev nplaum zoo: Qhov muaj cov pab pawg polar hydroxyl thiab ether bonds uas muaj nyob hauv cov saw hlau epoxy resin ua rau nws nplaum tau zoo rau ntau yam khoom. Qhov kev ntswj ntawm epoxy resin thaum kho yog qis, qhov kev ntxhov siab sab hauv tsim yog me me, thiab cov txheej tiv thaiv tsis yooj yim poob thiab ua tsis tiav.

· Cov khoom siv hluav taws xob: Lub kaw lus epoxy resin kho yog cov khoom siv rwb thaiv tsev zoo heev nrog cov khoom dielectric siab, tiv taus qhov xau ntawm qhov chaw, thiab tiv taus arc.

· Tiv taus pwm: Lub kaw lus epoxy resin kho tau zoo tiv taus feem ntau pwm thiab siv tau rau hauv cov huab cua sov hnyav.

02. Cov khoom siv phaj nylon phaj valve

Cov ntawv nylon yog cov tshuaj tiv thaiv corrosion heev thiab tau siv tau zoo hauv ntau daim ntawv thov xws li dej, av nkos, khoom noj thiab dej hiav txwv desalination.

· Kev ua tau zoo sab nraum zoov: Lub txheej nylon phaj tuaj yeem dhau qhov kev sim tshuaj tsuag ntsev. Nws tsis tau tev tawm tom qab raug muab tso rau hauv dej hiav txwv ntau tshaj 25 xyoo, yog li tsis muaj xeb rau cov khoom hlau.

· Kev tiv thaiv kev hnav: Kev tiv thaiv kev hnav zoo heev.

· Kev tiv thaiv kev cuam tshuam: Tsis muaj cim qhia tias yuav tev tawm thaum muaj kev cuam tshuam loj heev.

3. Cov txheej txheem txau

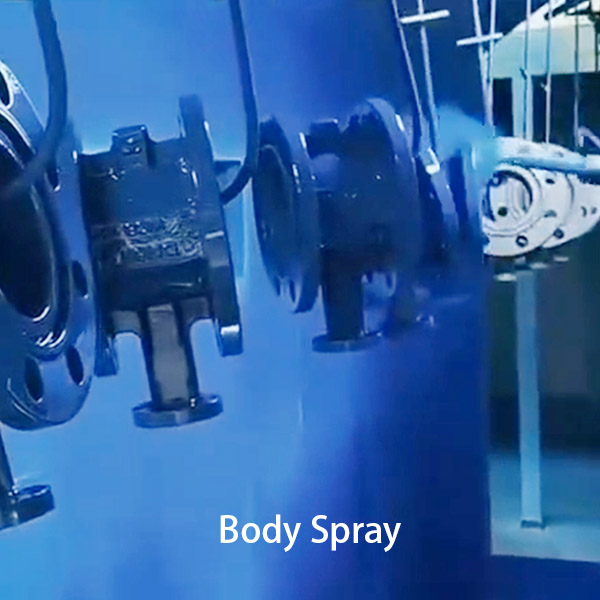

Cov txheej txheem txau yog ua ntej kho cov khoom ua haujlwm → tshem tawm cov plua plav → ua ntej cua sov → txau (primer - trimming - topcoat) → khov → txias.

Kev Tsuag Tshuaj Feem ntau siv cov tshuaj tsuag electrostatic. Raws li qhov loj ntawm cov khoom ua haujlwm, kev tsuag electrostatic tuaj yeem muab faib ua cov kab ntau lawm tshuaj tsuag hmoov electrostatic thiab chav tshuaj tsuag hmoov electrostatic. Ob txoj kev ua haujlwm zoo ib yam, thiab qhov sib txawv tseem ceeb yog txoj kev tig ntawm cov khoom ua haujlwm. Cov kab ntau lawm tshuaj tsuag siv cov saw hlau rau kev sib kis tsis siv neeg, thaum chav tshuaj tsuag raug tsa tes. Qhov tuab ntawm cov txheej txheem raug tswj ntawm 250-300. Yog tias qhov tuab tsawg dua 150 μm, kev ua haujlwm tiv thaiv yuav raug txo qis. Yog tias qhov tuab ntau dua 500 μm, qhov nplaum ntawm cov txheej txheem yuav txo qis, qhov kev tiv thaiv kev cuam tshuam yuav txo qis, thiab kev siv hmoov yuav nce ntxiv.