1. Kev Taw Qhiarau Npauj Npaim Valves

1.1. Lub Ntsiab Lus thiab Cov Haujlwm Tseem Ceeb

A npauj npaim valveyog ib lub cuab yeej uas tswj cov dej ntws hauv cov yeeb nkab. Nws raug tswj los ntawm kev tig lub disc ib feem plaub ntawm ib qho kev tig. Lawv feem ntau yog siv rau hauv cov ntawv thov uas lawv kaw sai.

1.2. Keeb Kwm ntawm Butterfly Valves

Cov npauj npaim valve tuaj yeem taug qab rov qab mus rau xyoo pua 19th. Tus qauv ntawm cov npauj npaim valve niaj hnub no tau yug los rau nruab nrab xyoo pua 20th. Tom qab ntau xyoo ntawm kev txhim kho, nws tau dhau los ua qhov kev daws teeb meem ntau yam rau kev tswj cov xov xwm hauv ntau yam lag luam.

Kev txhim kho thev naus laus zis ntawm cov npauj npaim valve tsis tau nres. Yav tom ntej, cov npauj npaim valve yuav sib dua thiab me dua. Lawv kuj tseem siv tau rau cov xwm txheej hnyav (xws li qhov siab heev thiab qhov kub tsawg heev). Tej zaum lawv tuaj yeem siv rau hauv cov ntawv thov tshiab hauv kev siv hluav taws xob rov ua dua tshiab, xws li lub zog hnub ci, lub zog cua thiab cov haujlwm hluav taws xob hydrogen ntsuab.

1.3. Kev siv cov npauj npaim valve hauv ntau yam lag luam

1.3.1. Kev Kho Dej thiab Kev Faib Dej

Hauv cov chaw kho dej thiab cov tshuab faib dej. Cov qhov dej npauj npaim yog qhov tseem ceeb heev. Lawv tswj thiab cais cov dej haus kom ntws tau zoo. Lawv qhov kev poob siab tsawg thiab lub peev xwm kaw ob txoj kev yog qhov tshwj xeeb tshaj yog rau kev ua kom muaj dej txaus.

1.3.2. Cov Tshuab HVAC

Hauv cov tshuab cua sov thiab cua txias (HVAC), cov li qub npauj npaim siv los tswj cov dej ntws. Lawv yooj yim ua rau lawv tsim nyog rau kev tswj cov dej txias thiab dej kub.

1.3.3. Cov Chaw Tsim Tshuaj thiab Petrochemical

Cov li qub peb npaug thiab cov li qub ua haujlwm siab tuaj yeem tswj tau ntau yam tshuaj lom neeg, suav nrog cov kua xeb thiab cov kua txhuam. Lawv lub peev xwm ua haujlwm ntawm qhov kub thiab txias heev ua rau lawv haum rau cov ntawv thov xws li kev ua tshuaj lom neeg, kev khaws cia, thiab kev xa khoom.

1.3.4. Kev Lag Luam Roj thiab Roj Av

Kev lag luam roj thiab roj av vam khom cov npauj npaim li qub rau cov ntawv thov xws li kev cais cov kav dej, kev tswj hwm kev ntws, thiab cov txheej txheem tank. Qhov sib xws ntawm cov npauj npaim li qub nrog ntau yam khoom siv ua kom lawv ua haujlwm zoo hauv kev lag luam roj thiab roj av.

1.3.5. Kev Ua Khoom Noj thiab Dej Haus

Kev huv huv yog qhov tseem ceeb tshaj plaws hauv kev ua zaub mov thiab dej haus. Cov npauj npaim valve nrog cov qauv huv thiab cov nplaim ci tuaj yeem siv los tswj kev huv thiab tiv thaiv kev ua qias tuaj thaum kov cov kua xws li kua txiv hmab txiv ntoo, cov khoom noj mis nyuj, thiab dej haus. Ob qho tib si roj hmab uas tau ntawv pov thawj wras thiab cov hlau tsis xeb qib zaub mov tuaj yeem ua tau raws li tus qauv no.

1.3.6. Kev Tsim Kho Tub Rog thiab Kev Ua Nkoj

Cov li qub ua los ntawm txhuas tooj liab yog tsim los rau kev siv hauv dej hiav txwv los tswj cov kab ke ballast, dej txias, thiab cov kav roj. Cov khoom siv tiv taus xeb ntawm cov li qub ua rau lawv zoo tagnrho rau kev siv hauv cov chaw nyob hauv dej hiav txwv uas nyuaj.

1.3.7. Cov Chaw Tsim Hluav Taws Xob

Hauv cov chaw tsim hluav taws xob, cov li qub npauj npaim siv rau hauv cov tshuab cua txias, cov kav dej pa, thiab cov tshuab desulfurization roj flue. Lawv muaj peev xwm tswj cov kua dej siab thiab kub siab.

1.3.8. Cov Chaw Kho Dej Pov Tseg

Cov npauj npaim valve yog qhov tseem ceeb rau kev tswj cov sludge, aeration, thiab cov dej ntws hauv cov chaw kho dej khib nyiab.

1.3.9. Kev Lag Luam Pulp thiab Ntawv

Kev lag luam pulp thiab ntawv tau txais txiaj ntsig los ntawm cov npauj npaim valve hauv cov txheej txheem xws li kev ua noj pulp, kev ua kom dawb, thiab kev rov qab siv tshuaj lom neeg. Lawv txoj kev tiv thaiv rau cov pulp thiab cov tshuaj lom neeg ua rau kev ua haujlwm zoo dua thiab lub neej ua haujlwm ntev dua.

2. Kev Tsim Kho ntawm Npauj Npaim Valve

2.1. Cov Cheebtsam ntawm Butterfly Valve

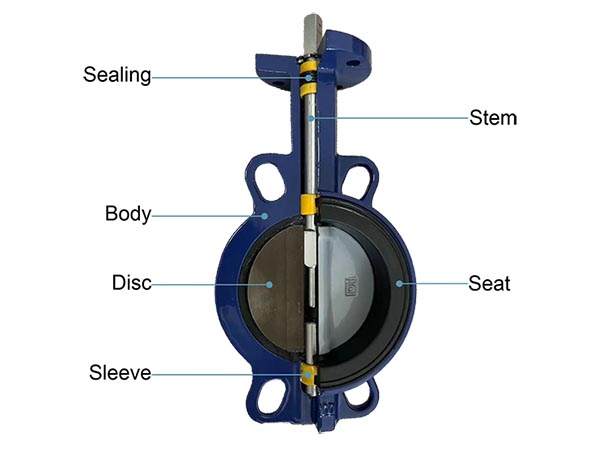

Cov khoom tseem ceeb muaj xws li:

Lub cev valve: Lub tsev uas muaj lwm yam khoom sab hauv.

Lub valve disc: Qhib thiab kaw los ntawm kev tig 90 degrees.

Qia: Txuas lub disc rau lub actuator.

Lub Rooj Zaum: Muab lub foob kom tiv thaiv kev xau.

2.2. Hom ntawm cov npauj npaim li qub raws li cov qauv

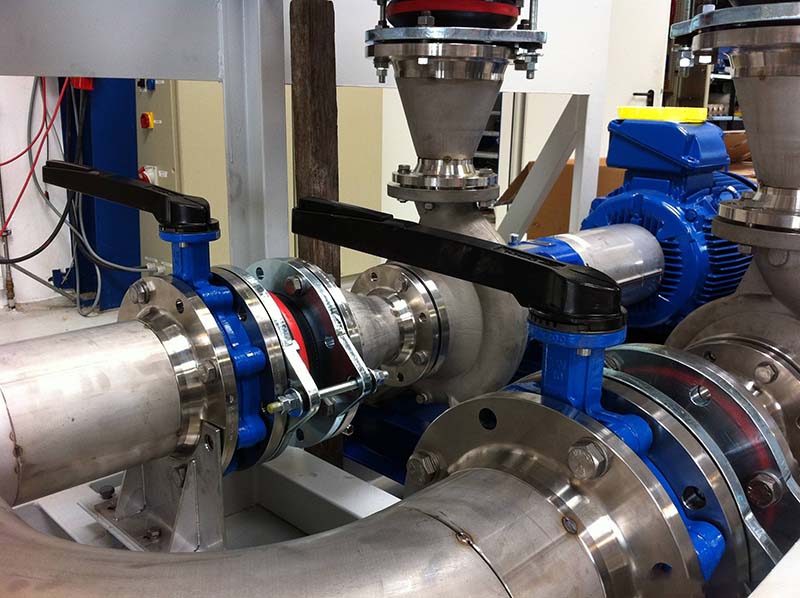

Hom Wafer: Nruab nrab ntawm cov flanges ntawm cov yeeb nkab thiab kho nrog bolts.

Hom Lug: Siv cov ntxig xov rau kev teeb tsa.

Hom flange: Muaj ob lub flanges thiab ntsia nrog cov yeeb nkab.

2.3. Cov ntaub ntawv ntawm cov npauj npaim li qub

Lub cev: cam khwb cia hlau, stainless hlau los yog carbon hlau.

Disc: Hlau zas (nickel-plated, nylon, PTFE, thiab EPDM, thiab lwm yam), WCB, stainless hlau, tooj liab.

Lub Rooj: Roj Hmab, Teflon lossis hlau.

3. Txoj cai ua haujlwm ntawm lub valve npauj npaim

3.1. Kev ua haujlwm ntawm lub valve npauj npaim

Lub valve npauj npaim ua haujlwm los ntawm kev tig lub disc uas tau teeb tsa rau ntawm lub qia nruab nrab. Qhov chaw ntawm lub disc txiav txim siab qhov kev tswj hwm dej ntws.

3.2. Hom kev tsav tsheb ntawm cov npauj npaim valve

Phau Ntawv Qhia: Ua haujlwm los ntawm kov thiab iav kab laug sab.

Pneumatic: Siv cua compressed.

Hluav Taws Xob: Tswj los ntawm lub cev muaj zog hluav taws xob.

Hydraulic: Tsav los ntawm lub zog ntawm cov kua dej (tsis tshua siv).

3.3. Cov txiaj ntsig thiab cov kev txwv ntawm cov npauj npaim valve

Qhov zoo: compact tsim (ntev qauv luv), tus nqi qis (khoom siv tsawg dua), ua haujlwm sai (90-degree tig).

Cov Kev Txwv: Cov npauj npaim valve tsis tuaj yeem siv los txiav cov khoom me me uas muaj zog, cov kua dej khov thiab cov khoom tsis huv.

3.4. Hom ntawm cov npauj npaim valves

3.4.1 Lub rooj zaum rov qab ua haujlwm tau zoo

Nta: Lub rooj zaum valve feem ntau yog ua los ntawm cov ntaub ntawv elastic xws li roj hmab thiab PTFE, thiab lub foob yog nruj.

Siv cov ntaub ntawv: kev siv siab tsawg thiab kev siv kub tsawg.

3.4.2.Lub valve npauj npaim ua haujlwm siab (ob chav offset npauj npaim valve)

Nta: Ob chav offset tsim, ruaj khov.

Siv cov ntaub ntawv: cov tshuab siab qis thiab nruab nrab.

3.4.3. Lub qhov dej npauj npaim peb npaug

Nta: Lub rooj zaum hlau foob tsis muaj kev sib txhuam.

Siv cov ntaub ntawv: kub heev thiab siab.

4. Kev teeb tsa thiab kev saib xyuas ntawm cov npauj npaim li qub

4.1 Txoj kev teeb tsa kom raug ntawm cov npauj npaim valve

Qhib lubnpauj npaim valvelub phaj ntawm lub kaum sab xis ntawm 0-90 degrees.

Xyuas kom tseeb tias muaj qhov chaw txaus los ntawm lwm cov khoom.

Xyuas kom tseeb tias lub phaj valve tsis kov lub flange yeeb nkab.

Xyuas kom tseeb tias qhov sib dhos thiab qhov sib nrug ntawm qhov tig ntawm lub disc.

4.2. Kev saib xyuas txhua hnub ntawm cov npauj npaim valve

Tshawb xyuas seb puas hnav thiab hloov yog tias tsim nyog.

Siv roj nplua nyeem rau cov khoom txav mus los raws li qhov xav tau.

4.3. Cov teeb meem thiab kev daws teeb meem uas feem ntau tshwm sim

Cov Xau: Xyuas kom lub rooj zaum ruaj khov.

Khaus: Ntxuav cov khib nyiab ntawm thaj chaw zaum thiab xyuas kom meej tias muaj roj nplua nyeem zoo.

5. Kev sib piv nrog lwm hom valve

5.1 Lub pob valve npauj npaim piv rau lub pob valve

Lub valve npauj npaim: Sib dua thiab me dua.

Lub pob valve: Haum dua rau kev ntws tag nrho, tuaj yeem siv ua cov kua nplaum thiab cov kua fibrous.

5.2. Lub qhov rooj vag thiab lub qhov rooj npauj npaim

Npauj npaim valve: Ua haujlwm sai.

Lub qhov rooj vag: Zoo dua rau kev qhib thiab kaw tag nrho.