Hauv kev lag luam tswj cov kua dej,npauj npaim li qubua lub luag haujlwm tseem ceeb hauv kev tswj hwm, kev coj ua, thiab kev cais cov kua dej, roj, thiab cov slurries hauv cov kav dej. Lub flanged butterfly valve yog ib hom kev sib txuas, muaj cov flanges sib xyaw rau ob qho kawg ntawm lub cev valve, uas tso cai rau kev sib txuas ruaj ntseg rau cov yeeb nkab flanges.

Lub mechanism ntawm kev tig ib lub quarter-turn ntawm ib lubflanged npauj npaim valvenws txawv ntawm cov li qub linear xws li lub rooj vag lossis lub ntiaj teb li qub, muab cov txiaj ntsig zoo hauv kev ceev thiab qhov chaw txuag tau.

Tsab xov xwm no yuav nkag mus rau hauv cov ntsiab lus ntawm flanged butterfly valves, npog lawv cov qauv tsim, hom, cov ntaub ntawv, daim ntawv thov, qhov zoo thiab qhov tsis zoo, kev teeb tsa, kev saib xyuas, kev sib piv nrog lwm cov li qub, thiab cov qauv yav tom ntej.

1. Lub Ntsiab Lus thiab Txoj Cai Ua Haujlwm

Lub valve flanged butterfly yog lub valve tig 90-degree uas muaj lub disc uas tswj cov kua dej ntws los ntawm kev tig ntawm lub qia. Lub cev valve muaj cov flanges ntawm ob qho kawg rau kev sib txuas ncaj qha rau cov kav dej. Cov valve flange butterfly muaj cov flanges tsa lossis tiaj tiaj nrog cov qhov bolt, muab kev sib txuas ruaj khov thiab ruaj khov dua rau cov ntawv thov qis, nruab nrab, thiab siab, nrog rau cov kab uas hla me, nruab nrab, thiab loj.

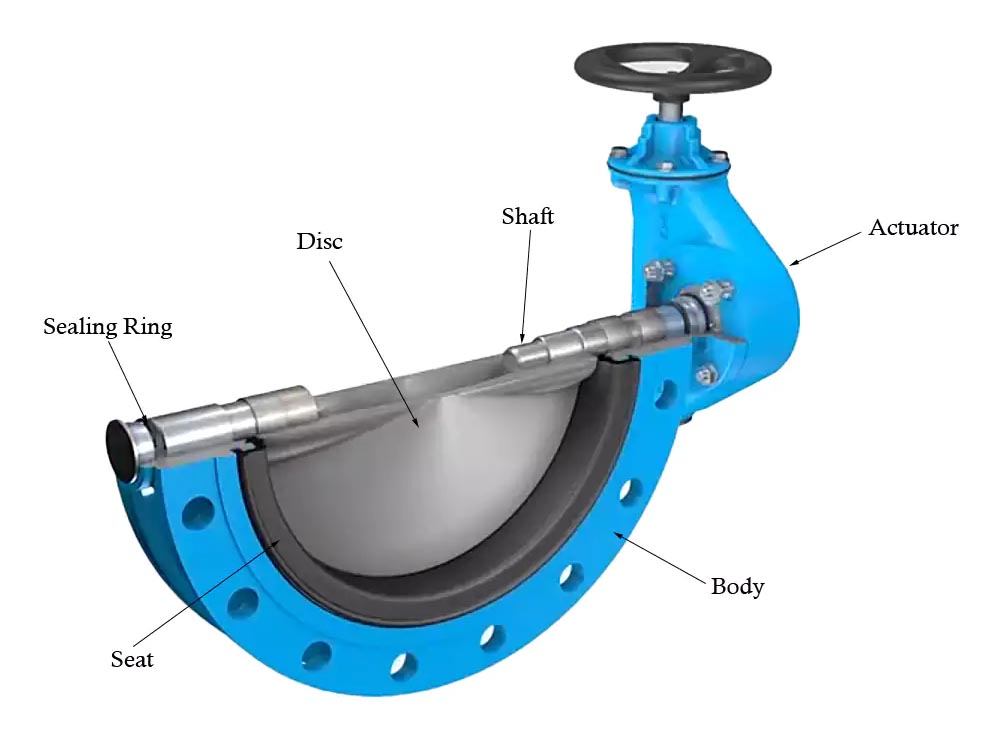

Lub hauv paus ntsiab lus ua haujlwm yooj yim thiab ua tau zoo. Lub valve muaj lub cev valve, lub disc valve, lub qia valve, lub rooj zaum valve, thiab lub actuator. Thaum lub tes tuav lossis lub iav raug siv, lossis lub qia valve raug tig los ntawm lub actuator tsis siv neeg, lub disc valve tig los ntawm qhov chaw sib luag rau txoj kev ntws (qhib tag nrho) mus rau qhov chaw perpendicular (kaw tag nrho). Thaum qhib, lub disc valve raug teeb tsa nrog lub raj xa dej, txo qhov kev tiv thaiv ntws thiab kev poob siab. Thaum kaw, lub disc valve kaw rau ntawm lub rooj zaum hauv lub cev valve.

Lub tshuab no tso cai rau lub valve ua haujlwm sai, feem ntau tsuas yog xav tau 90-degree tig, ua rau nws sai dua li ntau lub valve tig. Cov flanged npauj npaim valves tuaj yeem tswj tau ob txoj kev ntws thiab feem ntau yog nruab nrog cov rooj zaum resilient lossis hlau kom ntseeg tau tias kaw nruj. Lawv tus qauv tsim ua rau lawv tsim nyog rau cov kab ke uas xav tau kev hloov pauv ntau zaus lossis qhov chaw tsawg.

2. Cov Cheebtsam

Cov khoom tseem ceeb muaj xws li:

- Lub cev valveLub tsev sab nraud, feem ntau yog ob lub flange, muab kev sib txuas ntawm cov qauv thiab muaj cov khoom sab hauv. Cov hlau carbon yog siv rau kev siv dav dav, cov hlau tsis xeb rau kev tiv thaiv xeb, nickel-aluminium bronze rau cov chaw nyob hauv dej hiav txwv, thiab cov hlau alloy rau cov xwm txheej hnyav.

- Lub Rooj Vag Disc:Lub ntsiab lus tig, muaj nyob rau hauv ob qho tib si streamlined lossis tiaj tus qauv, tswj cov dej ntws. Lub disc tuaj yeem nyob hauv nruab nrab lossis offset kom txhim kho kev ua tau zoo. Stainless hlau, txhuas tooj dag, lossis coated nrog nylon rau kev txhim kho kev hnav tsis kam.

- QiaLub qhov txuas lub valve disc rau lub actuator xa lub zog tig. Cov hlau tsis xeb lossis cov hlau alloys muaj zog heev tiv taus lub zog torque.

Feem ntau siv cov kav hlau los yog ob daim, nruab nrog cov foob kom tiv thaiv kev xau.

- Lub Rooj Zaum: Qhov chaw sib khi yog ua los ntawm cov khoom siv elastomeric xws li EPDM lossis PTFE. EPDM (-20°F txog 250°F), BUNA-N (0)°F txog 200°F), Viton (-10)°F txog 400°F), los yog PTFE (-100°F txog 450°F) siv rau cov foob mos; cov ntaub ntawv hlau xws li stainless hlau lossis Inconel siv rau cov foob tawv kub siab.

- Tus ua haujlwmUa haujlwm tes (kov, iav) lossis siv hluav taws xob (pneumatic, hluav taws xob).

- Cov khoom siv thiab gaskets: Xyuas kom meej tias cov khoom sib txuas ntawm cov khoom thiab ntawm cov flange sib txuas muaj qhov xau.

Cov khoom no ua haujlwm ua ke los muab kev tswj hwm kev ntws zoo.

3. Hom Flanged Butterfly Valves

Cov flanged npauj npaim li qub tuaj yeem muab faib ua pawg raws li cov hauv qab no raws li kev sib dhos ntawm disc, txoj kev ua haujlwm, thiab hom lub cev.

3.1 Kev Sib Tho

- Concentric (xoom offset): Lub qia valve txuas mus rau hauv nruab nrab ntawm lub disc thiab muaj lub rooj zaum resilient. Lub valve no yog tsim rau cov ntawv thov qis-siab nrog qhov kub txog li 250°F.

- Ob chav offset: Lub valve qia yog offset tom qab lub disc thiab tawm ntawm qhov chaw, txo qhov hnav ntawm lub rooj zaum. Lub valve no yog tsim rau cov ntawv thov nruab nrab-siab thiab qhov kub txog li 400°F.

- Peb npaug offset: Lub kaum sab xis ntawm lub rooj zaum uas nce ntxiv ua rau lub foob hlau-rau-hlau. Lub valve no haum rau qhov siab (txog li Chav Kawm 600) thiab qhov kub siab (txog li 1200°F) daim ntawv thov thiab ua tau raws li qhov yuav tsum tau ua kom tsis muaj dej xau.

3.2 Txoj Kev Ua Haujlwm

Cov hom kev ua haujlwm suav nrog phau ntawv, pneumatic, hluav taws xob, thiab hydraulic kom haum rau ntau yam kev ua haujlwm.

4. Kev Siv Hauv Kev Lag Luam

Flanged npauj npaim li qub yog siv dav hauv cov haujlwm hauv qab no:

- Kev Kho Dej thiab Dej Pov Tseg: Siv rau kev tswj cov dej ntws hauv cov chaw kho dej thiab cov txheej txheem hloov pauv. - Kev Ua Tshuaj: Kev tswj cov kua qaub, alkalis, thiab cov kuab tshuaj xav tau cov ntaub ntawv tiv taus xeb.

- Roj & Roj Av: Cov kav dej rau roj av nyoos, roj av ntuj, thiab cov txheej txheem refining.

- Cov Txheej Txheem HVAC: Tswj cov cua thiab dej ntws hauv cov tes hauj lwm cua sov thiab cua txias.

- Kev Tsim Hluav Taws Xob: Tswj cov pa dej, dej txias, thiab roj.

- Khoom Noj & Dej Haus: Tsim qauv huv rau kev siv kua dej aseptic.

- Tshuaj: Kev tswj hwm meej hauv qhov chaw tsis muaj kab mob.

- Marine & Pulp & Ntawv: Siv rau dej hiav txwv, pulp, thiab kev ua tshuaj lom neeg.

5. Cov Zoo thiab Cov Tsis Zoo ntawm Flange Butterfly Valves

5.1 Cov Zoo:

- Kev cog lus me me thiab lub teeb yuag, txo cov nqi teeb tsa thiab qhov chaw xav tau.

- Kev ua haujlwm ceev ceev thiab teb sai.

- Tus nqi qis dua rau cov diameters loj dua.

- Kev poob siab tsawg thaum qhib, txuag hluav taws xob thiab ua haujlwm tau zoo.

- Haum rau kev hloov kua nrog kev ua tau zoo heev.

- Yooj yim rau kev tswj hwm thiab sib xws nrog cov tshuab automation.

5.2 Qhov Tsis Zoo:

- Lub disc valve thaiv txoj kev ntws thaum qhib, ua rau qee qhov kev poob siab. - Muaj peev xwm txwv tsis pub siv cov khoom siv siab, uas ua rau cavitation.

- Cov rooj zaum mos mos hnav sai dua hauv cov khoom siv abrasive.

- Kaw sai dhau yuav ua rau muaj dej ntau dhau.

- Qee qhov kev tsim qauv xav tau qhov pib siab dua, xav tau cov actuators muaj zog dua.

6. Yuav Ua Li Cas Nruab Ib Lub Npauj Npaim Valve

Thaum lub sijhawm teeb tsa, teeb tsa lub valve flange nrog lub yeeb nkab flange, xyuas kom meej tias cov qhov bolt sib phim.

Muab ib lub gasket rau sealing.

Ruaj ntseg nrog bolts thiab txiv ntoo, zawm kom sib npaug kom tiv thaiv kev cuam tshuam.

Cov li qub ob-flange xav tau kev sib dhos ntawm ob sab tib lub sijhawm; cov li qub hom lug tuaj yeem raug bolted ib sab ib zaug.

Ua ntej nias lub valve, xyuas kom lub disc txav tau yooj yim.

Thaum ntsia ntsug, lub qia valve yuav tsum tau muab tso rau kab rov tav kom tiv thaiv cov av noo.

Ua raws li cov lus qhia ntawm cov chaw tsim khoom thiab cov qauv kev sim xws li API 598.

7. Cov Qauv thiab Cov Cai

Flanged npauj npaim li qubyuav tsum ua raws li cov qauv kev nyab xeeb thiab kev sib koom tes:

- Tsim: API 609, EN 593, ASME B16.34. - Kev xeem: API 598, EN 12266-1, ISO 5208.

- Flanges: ASME B16.5, DIN, JIS.

- Cov ntawv pov thawj: CE, SIL3, API 607(kev nyab xeeb hluav taws).

8. Kev Sib Piv Nrog Lwm Cov Li Qub

Piv rau cov qhov rooj vag, cov qhov rooj flanged npauj npaim ua haujlwm sai dua thiab muaj peev xwm throttling, tab sis tsis tshua muaj zog rau kev ntws.

Piv rau cov pob li qub, lawv pheej yig dua rau cov kab uas loj dua, tab sis muaj kev poob siab ntau dua thaum qhib.

Cov li qub thoob ntiaj teb muab kev ua kom raug zoo dua, tab sis loj dua thiab kim dua.

Zuag qhia tag nrho, npauj npaim li qub zoo heev rau qhov chaw txwv thiab cov nqi-rhiab heev.