Cov npauj npaim resilientyog hom npauj npaim valve uas siv dav tshaj plaws hauv cov kav dej kev lag luam. Lawv siv cov khoom siv elastic xws li roj hmab ua qhov chaw kaw, vam khom "kev ua kom cov khoom siv rov qab zoo" thiab "kev sib zog ntawm cov qauv" kom ua tiav kev ua haujlwm kaw.

Tsab xov xwm no tsis yog tsuas yog qhia txog cov qauv, kev siv, thiab cov ntaub ntawv xwb, tab sis kuj tseem tshuaj xyuas lawv los ntawm kev paub dav dav mus rau kev xav tob tob.

1. Kev Nkag Siab Yooj Yim Txog Cov Npauj Npaim Uas Muaj Zog (Kev Piav Qhia Luv Luv)

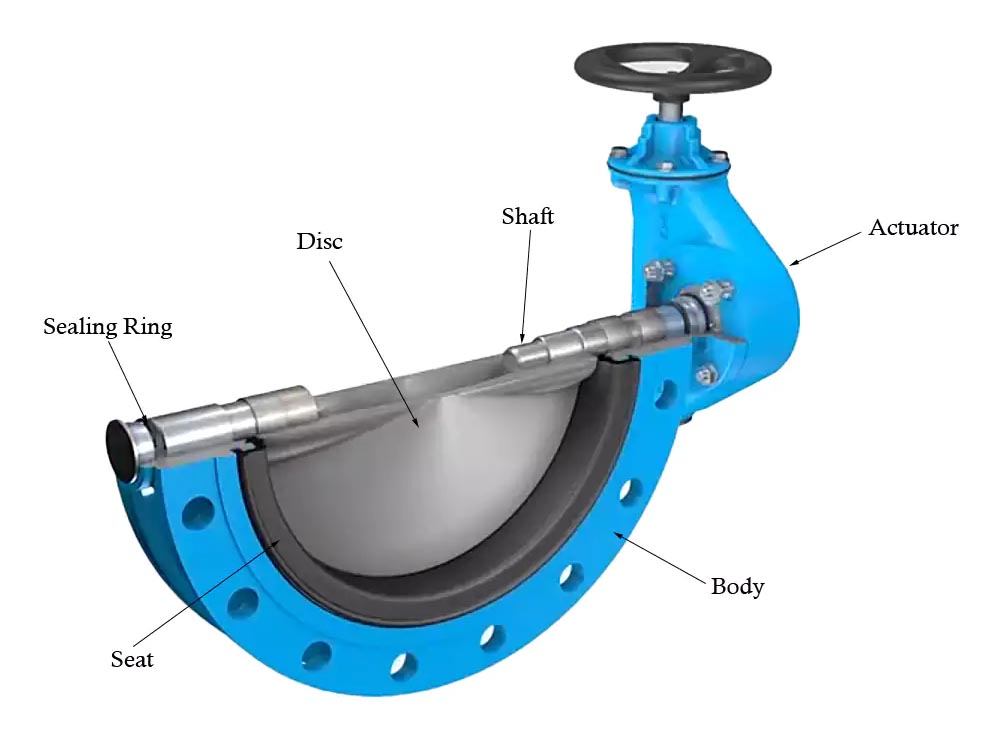

1.1 Cov Qauv Tseem Ceeb

Lub cev valve:Feem ntau yog hom wafer, hom lug, lossis hom flanged.

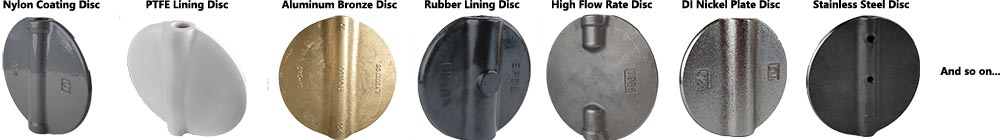

Lub Rooj Vag Disc:Ib lub phaj hlau puag ncig uas nias lub rooj zaum roj hmab thaum kaw kom tsim tau lub foob.

Lub Rooj Zaum Valve:Ua los ntawm cov ntaub ntawv elastic xws li NBR / EPDM / PTFE / Roj Hmab Lined, ua haujlwm ua ke nrog lub valve disc.

Lub Qhov (Valve Stem):Feem ntau siv ib lub ncej lossis ob lub ncej tsim.

Tus ua haujlwm:Kov, iav kab, hluav taws xob, pneumatic, thiab lwm yam.

1.2 Cov yam ntxwv feem ntau

Qib sealing feem ntau ua tiav xoom xau.

Tus nqi qis thiab ntau yam kev siv.

Feem ntau siv rau hauv cov tshuab qis mus rau nruab nrab xws li dej, cua txias, HVAC, thiab kev lag luam tshuaj lom neeg.

2. Kev nkag siab yuam kev txog Cov Npauj Npaim Uas Muaj Peev Xwm Rov Qab Tau

2.1 Lub ntsiab lus ntawm kev sib khi yog roj hmab resilience

Muaj coob tus neeg ntseeg tias: "Cov rooj zaum uas ruaj khov vam khom cov roj hmab uas ua kom ruaj khov."

Lub ntsiab lus tseeb ntawm kev kaw yog:

Lub cev valve + qhov deb ntawm qhov chaw nruab nrab ntawm lub qia valve + qhov tuab ntawm lub disc valve + txoj kev ntxig lub rooj zaum valve

Ua ke tsim ib qho "tswj kev sib zog tswj cheeb tsam".

Hais yooj yim xwb:

Cov roj hmab yuav tsum tsis txhob xoob dhau los yog nruj dhau; nws vam khom rau "cheeb tsam nias kaw" uas tswj los ntawm kev ua haujlwm raug.

Vim li cas qhov no thiaj tseem ceeb?

Kev sib zog tsis txaus: Lub valve xau thaum kaw.

Kev nias ntau dhau: lub zog torque siab heev, cov roj hmab laus ua ntej lub sijhawm.

2.2 Lub disc uas zoo li lub disc uas du thiab zoo dua puas siv hluav taws xob tau zoo dua?

Kev pom dav dav: Cov discs valve streamlined tuaj yeem txo qhov poob siab.

Qhov no muaj tseeb raws li "fluid mechanics" txoj kev xav, tab sis nws tsis siv tau rau qhov kev siv tiag tiag ntawm Resilient Butterfly Valves.

Vim li cas:

Qhov ua rau lub valve npauj npaim poob siab tsis yog vim lub valve disc zoo li cas, tiam sis yog vim "micro-channel tunnel effect" uas tshwm sim los ntawm kev sib txhuam ntawm lub rooj zaum roj hmab valve. Lub valve disc nyias dhau lawm yuav ua rau lub valve tsis muaj zog txaus, ua rau cov kab sealing tsis sib txuas thiab xau.

Lub disc valve uas zoo li lub valve qub tuaj yeem ua rau muaj qhov ntse ntse ntawm cov roj hmab, ua rau nws lub neej luv dua.

Yog li ntawd, qhov kev tsim cov npauj npaim uas muaj qhov rooj mos mos muab qhov tseem ceeb rau "kev ruaj khov ntawm kab sealing" dua li kev ua kom yooj yim.

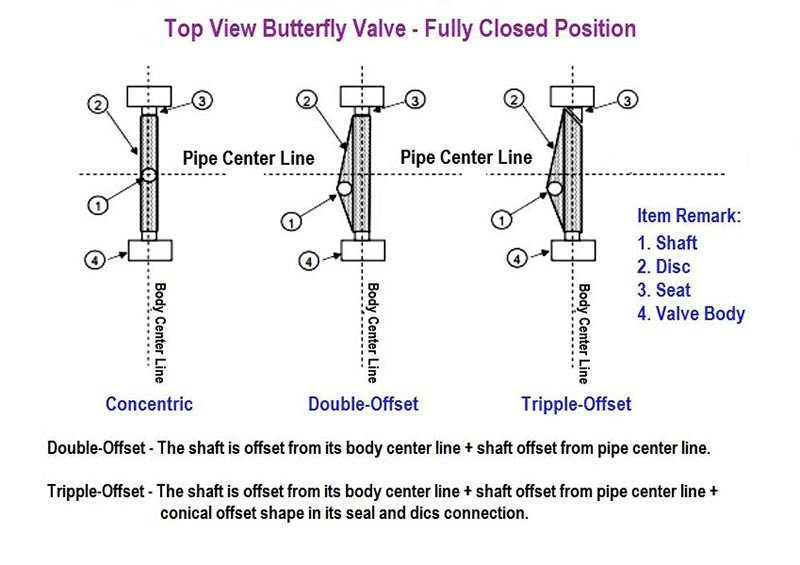

2.3 Cov npauj npaim uas muaj qhov chaw zaum mos tsuas muaj cov qauv hauv nruab nrab xwb

Nws feem ntau hais hauv online tias cov li qub npauj npaim eccentric yuav tsum siv cov hlau tawv.

Txawm li cas los xij, kev paub txog kev tsim kho hauv ntiaj teb tiag tiag qhia tau tias:

Qhov ob chav eccentricity ua rau lub neej ntawm Resilient Butterfly Valves ntev dua.

Vim li cas:

Ob chav eccentricity: Lub valve disc tsuas yog kov cov roj hmab thaum lub sijhawm kawg 2-3 ° ntawm kev kaw, txo qhov kev sib txhuam.

Lub zog qis dua, ua rau kev xaiv actuator pheej yig dua.

2.4 Qhov kev xav tseem ceeb rau lub rooj zaum roj hmab yog "lub npe khoom siv"*

Cov neeg siv feem ntau tsuas yog tsom mus rau:

EPDM

NBR

Viton (FKM)

Tab sis qhov tseeb tiag cuam tshuam rau lub neej yog:

2.4.1 Qhov nyuaj ntawm ntug dej hiav txwv:

Piv txwv li, qhov nyuaj ntawm EPDM ntawm Shore A tsis yog "qhov mos dua qhov zoo dua." Feem ntau, 65-75 yog qhov sib npaug zoo tshaj plaws, ua tiav xoom qhov xau ntawm qhov siab qis (PN10-16).

Mos dhau: Lub zog qis tab sis yooj yim dua. Hauv qhov siab siab (> 2 MPa) lossis qhov chaw tsis ruaj khov, roj hmab mos raug nias ntau dhau, ua rau extrusion deformation. Ntxiv mus, qhov kub siab (> 80 ° C) ua rau roj hmab mos dua.

Nyuaj dhau: Nyuaj rau kev kaw, tshwj xeeb tshaj yog nyob rau hauv cov tshuab qis-siab (<1 MPa), qhov twg cov roj hmab tsis tuaj yeem raug nias kom txaus los ua qhov sib txuas airtight, ua rau muaj micro-leakage.

2.4.2 Qhov kub thiab txias ntawm kev sib xyaw ua ke thiab lub sijhawm kho

Qhov kub thiab txias ntawm kev sib xyaw ua ke ntawm cov roj hmab thiab lub sijhawm kho kom zoo tswj kev sib txuas ntawm cov saw hlau molecular, uas cuam tshuam ncaj qha rau kev ruaj khov ntawm cov qauv network thiab kev ua haujlwm ntev. Qhov ntau thiab tsawg yog 140-160 ° C, 30-60 feeb. Qhov kub siab dhau lossis qis dhau ua rau kev kho tsis sib xws thiab ua rau laus sai. Peb lub tuam txhab feem ntau siv ntau theem ntawm kev sib xyaw ua ke (ua ntej kho ntawm 140 ° C, ua raws li kev kho tom qab kho ntawm 150 ° C). 2.4.3 Cov Txheej Txheem Sib Nqus

Cov txheej txheem nias yog hais txog qhov sib piv ntawm kev hloov pauv mus tas li uas roj hmab raug kev ntxhov siab tas li (feem ntau yog 25% -50% kev nias, sim ntawm 70 ° C / 22 teev, ASTM D395) thiab tsis tuaj yeem rov qab tau tag nrho. Tus nqi zoo tshaj plaws rau cov txheej txheem nias yog <20%. Tus nqi no yog "lub qhov ncauj" rau kev kaw lub valve mus sij hawm ntev; kev siab siab ntev ua rau muaj qhov sib txawv mus tas li, tsim cov ntsiab lus xau.

2.4.4 Lub Zog Tensile

A. Lub zog tensile (feem ntau >10 MPa, ASTM D412) yog qhov siab tshaj plaws uas cov roj hmab tuaj yeem tiv taus ua ntej tawg tensile, thiab yog qhov tseem ceeb rau kev tiv thaiv kev hnav thiab kev tsim kua muag ntawm lub rooj zaum valve. Cov roj hmab thiab cov pa roj carbon dub piv txiav txim siab lub zog tensile ntawm lub rooj zaum valve.

Hauv cov npauj npaim li qub, nws tiv taus kev txiav los ntawm ntug ntawm lub valve disc thiab cov kua dej cuam tshuam.

2.4.5 Qhov txaus ntshai tshaj plaws ntawm cov npauj npaim valve yog qhov xau.

Hauv kev raug xwm txheej engineering, qhov xau feem ntau tsis yog qhov teeb meem loj tshaj plaws, tab sis yog qhov nce ntawm torque.

Qhov ua rau lub system tsis ua haujlwm tiag tiag yog:

Kev nce siab ntawm lub zog torque sai sai → kev puas tsuaj ntawm cov iav worm → kev ua txhaum ntawm lub actuator → kev cuam tshuam ntawm lub valve

Vim li cas lub torque mam li nce ntxiv?

- Kev nthuav dav ntawm lub rooj zaum valve kub heev

- Kev nqus dej thiab nthuav dav ntawm cov roj hmab (tshwj xeeb tshaj yog EPDM tsis zoo)

- Kev hloov pauv tas mus li ntawm cov roj hmab vim yog kev nias mus sij hawm ntev

- Tsim tsis zoo ntawm qhov sib txawv ntawm lub valve stem thiab lub valve disc

- Lub rooj zaum valve tsis tau tawg zoo tom qab hloov pauv

Yog li ntawd, "torque curve" yog ib qho cim qhia tseem ceeb heev.

2.4.6 Qhov tseeb ntawm lub cev valve machining tsis yog qhov tsis tseem ceeb.

Muaj ntau tus neeg ntseeg yuam kev tias qhov kev sib khi ntawm cov npauj npaim mos mos feem ntau yog nyob ntawm roj hmab, yog li qhov yuav tsum tau ua kom raug ntawm lub cev valve tsis siab.

Qhov no yuam kev kiag li.

Qhov tseeb ntawm lub cev valve cuam tshuam rau:

Qhov tob ntawm lub rooj zaum valve → qhov sib txawv ntawm qhov sib txawv ntawm qhov sib khi, ua rau muaj kev tsis sib haum xeeb thaum qhib thiab kaw.

Tsis txaus chamfering ntawm lub groove ntug → khawb thaum lub sij hawm teeb tsa lub rooj zaum valve

Yuam kev nyob nruab nrab ntawm lub valve disc → kev sib cuag ntau dhau hauv zos

2.4.7 Lub hauv paus ntawm "cov roj hmab tag nrho / PTFE lined npauj npaim li qub" yog lub valve disc.

Lub hauv paus ntawm cov qauv roj hmab lossis PTFE uas muaj cov qauv tsis yog "muaj thaj chaw loj dua uas zoo li tiv taus xeb," tab sis yog los thaiv cov khoom nruab nrab kom tsis txhob nkag mus rau hauv cov kab me me hauv lub cev valve. Ntau yam teeb meem nrog cov npauj npaim pheej yig tsis yog vim cov roj hmab tsis zoo, tab sis:

Qhov "qhov sib txawv zoo li wedge" ntawm qhov sib tshuam ntawm lub rooj zaum valve thiab lub cev tsis tau raug kho kom zoo.

Kev yaig dej mus sij hawm ntev → cov kab nrib pleb me me → cov roj hmab tawg thiab bulging

Kauj ruam kawg yog qhov ua tsis tiav hauv zos ntawm lub rooj zaum valve.

3. Vim li cas cov Resilient Butterfly Valves thiaj siv thoob ntiaj teb?

Ntxiv rau tus nqi qis, peb qhov laj thawj tob dua yog:

3.1. Kev kam rau ua txhaum siab heev

Piv rau cov hlau foob, cov roj hmab foob, vim lawv qhov elasticity zoo heev, muaj kev kam rau siab rau kev teeb tsa deviations thiab me ntsis deformations.

Txawm tias cov yeeb nkab ua ntej qhov yuam kev, flange deviations, thiab tsis sib npaug ntawm bolt kev ntxhov siab raug nqus los ntawm elasticity ntawm cov roj hmab (ntawm chav kawm, qhov no yog txwv thiab tsis xav tau, thiab yuav ua rau qee qhov kev puas tsuaj rau cov yeeb nkab thiab lub valve hauv lub sijhawm ntev).

3.2. Kev hloov pauv zoo tshaj plaws rau kev hloov pauv ntawm lub zog ntawm lub kaw lus

Cov roj hmab foob tsis "nkig" li cov hlau foob; lawv cia li them cov kab sib khi thaum lub sijhawm hloov pauv siab.

3.3. Tus nqi qis tshaj plaws ntawm lub neej voj voog

Cov npauj npaim uas kaw ruaj khov yog cov khoom siv ruaj khov dua, tab sis tus nqi thiab cov nqi actuator siab dua.

Piv txwv li, tag nrho cov nqi peev thiab kev saib xyuas ntawm Resilient Butterfly Valves pheej yig dua.

4. Xaus Lus

Tus nqi ntawmCov Npauj Npaim Uas Muaj Peev Xwm Rov Qab Tautsis yog "kev kaw mos mos" xwb

Cov li qub uas kaw tau mos mos yuav zoo li yooj yim, tab sis cov khoom zoo heev tiag tiag yog txhawb nqa los ntawm kev xav txog kev ua haujlwm zoo, suav nrog:

Kev tsim qauv cheeb tsam nruj meej

Kev ua haujlwm roj hmab tswj tau

Kev sib phim geometric ntawm lub cev valve thiab qia

Cov txheej txheem sib dhos lub rooj zaum valve

Kev tswj hwm lub zog

Kev kuaj lub neej voj voog

Cov no yog cov yam tseem ceeb uas txiav txim siab qhov zoo, tsis yog "lub npe khoom" thiab "qauv tsos".

LUS CEEV:* COV NTAUB NTAWV yog hais txog lub vev xaib no:https://zfavalves.com/blog/key-factors-that-determine-the-quality-of-soft-seal-butterfly-valves/

Lub sijhawm tshaj tawm: Lub Kaum Ob Hlis-09-2025