A tag nrho lined npauj npaim valventa ib tug tag nrho lined qauv nyob rau hauv lub valve lub cev. Cov qauv no yog tsim tshwj xeeb rau kev siv corrosion-resistant.

"Fully lined" txhais tau hais tias tsis yog tsuas yog lub disc kaw nkaus xwb, tab sis kuj lub rooj zaum tau kaw tag nrho, ua kom muaj kev sib cais tag nrho ntawm cov xov xwm thiab cov hlau.

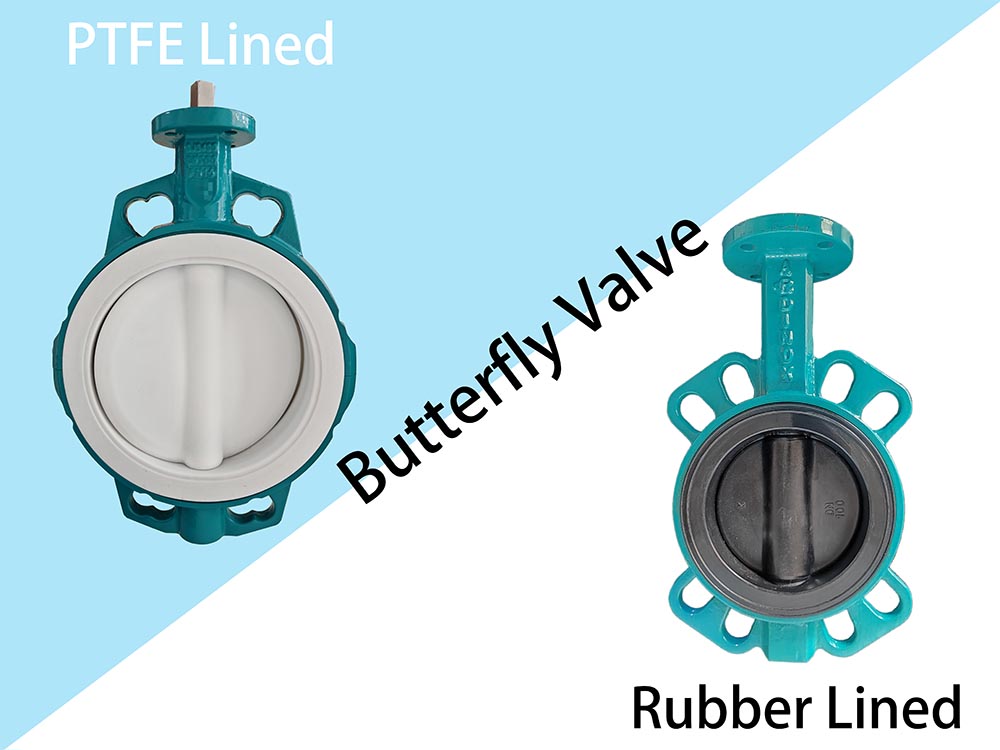

1. Ob yam khoom siv hauv ob sab phlu

ib. PTFE (polytetrafluoroethylene, perfluoroplastic) hauv ob sab phlu npauj npaim valve

b. Rubber hauv ob sab phlu npauj npaim valve

| Khoom siv: | Polytetrafluoroethylene (PTFE) hauv ob sab phlu | Rubber hauv ob sab phlu (piv txwv li, EPDM, Viton, NBR) |

| Txheej txheej txheej | Molten PTFE / PFA yog nchuav rau hauv dovetail zawj ntawm lub cev / disc, ua tiav daim ntawv cog lus seamless. | Nws yog ces ncaj qha vulcanized (kub-kho) mus rau cov hlau, tsim ib tug nruj, ib tug sealing. |

| Cov yam ntxwv tseem ceeb | - Zoo heev corrosion kuj (tiv taus ze li ntawm tag nrho cov acids, bases, thiab organic solvents) - Kub kub tsis kam (kev khiav hauj lwm kub mus txog 180°C) - Tsis tshua muaj kev sib txhuam coefficient thiab tsis-stick zog, haum rau high-purity media

| - Zoo elasticity thiab zoo sealing kev ua tau zoo (yooj yim kom ua tiav xoom to) - Tus nqi qis thiab zoo hnav tsis kam rau cov xov xwm uas tsis yog corrosive - Tsawg kub tsis kam (feem ntau -20°C rau 180°C, nyob ntawm seb hom roj hmab)

|

| Siv tau Media | Cov kua qaub muaj zog (xws li sulfuric acid thiab hydrochloric acid), cov hauv paus muaj zog, cov kuab tshuaj organic, cov kua dej purity siab | dej, dej khib nyiab, tsis muaj zog acids thiab bases, slurries, thiab zaub mov-qib xov xwm |

| Tej kev siv | Kev lag luam tshuaj (acid thiab alkali hloov), Pharmaceutical Industry (high-purity material transfer) | Kev kho dej (kev kho dej khib nyiab, kais dej), HVAC Systems, Khoom noj khoom haus thiab dej haus kev lag luam, mining (slurry hloov) |

2. Cov txheej txheem nthuav dav rau PTFE-lined Valve Discs

2.1 Hlau Disc Kev Npaj

a.. Cam khwb cia lossis tshuab cov hlau disc core, xyuas kom meej qhov chaw huv si thiab tsis muaj roj thiab paug.

b.. Txiav grooves (dovetail puab) ntawm qhov chaw tseem ceeb los muab cov ntsiab lus thauj tog rau nkoj rau PTFE txhaj tshuaj thiab tiv thaiv kom tsis txhob poob tawm.

2.2 PTFE Pwm Moulding thiab Preforming

ib. Muab ib tug ua tib zoo xam tus nqi ntawm PTFE hmoov (los yog premix) rau hauv pwm, ntxig cov hlau npauj npaim valve core, thiab ces ntxiv PTFE hmoov.

b. Maj mam siv lub tshuab nqus tsev (kua pa) thiab siab (compression lossis isostatic nias) los tsim ib lub embryo ntsuab. Isostatic molding: Muab cov pwm tso rau hauv dej thiab siv lub siab sib xws ntawm txhua sab (dej siab conduction) kom ntseeg tau tias cov qauv tsis sib xws thiab ntom ntom (porosity tsawg li <1%).

2.3 Sintering thiab kho

ib. Muab cov embryo ntsuab tso rau hauv qhov cub thiab sinter ntawm 380 ° C rau 5-24 teev (tuaj yeem nce qhov kub kom tsis txhob tawg).

b. Maj mam txias rau chav sov kom tso cai rau PTFE kom crystallize thiab fuse nrog cov tub ntxhais hlau, tsim cov txheej txheem seamless (thickness tswj tau 3-10 hli, kho raws li lub tshuab nqus tsev).

2.4 Machining thiab Finishing:

Siv lub tshuab dhos lossis CNC tshuab los tshuab lub puab thiab sab nraud los xyuas kom meej tias cov disc thiab lub rooj zaum haum zoo kawg nkaus (kev ua siab ntev, xws li ± 0.01mm).

2.5 Kev Ntsuam Xyuas thiab Kev Ntsuas Zoo:

ib. Kev Ntsuas Thickness: Xyuas kom muaj qhov tsawg kawg nkaus ntawm 3mm, lossis raws li kev cai.

b. Spark Test: 35,000 volts rau kev ntsuas nruj (tsis muaj kev puas tsuaj qhia tau txais).

c. Lub Nqus Tsev / Lub Zog Test: Simulates kev khiav hauj lwm tej yam kev mob los xyuas cov dej xau thiab permeability (raws li EN 12266-1 los yog API 598).

d. Conductivity Test (optional): Surface resistance <10⁶Ω rau cov ntaub ntawv pov thawj tawg.

3. Cov txheej txheem nthuav dav rau EPDM-lined Discs

3.1 Hlau Disc Kev Npaj

ib. Cam khwb cia lossis tshuab cov tub ntxhais hlau kom huv si, tsis muaj xeb.

b. Xuab zeb los yog tshuaj pleev xim rau saum npoo (roughness Ra 3-6μm) los txhawb EPDM adhesion.

3.2 EPDM Compound Application thiab Preforming

Uncured EPDM compound (daim ntawv los yog kua) yog muab tso rau hauv pwm, qhwv ib ncig ntawm cov tub ntxhais hlau. Siv compression molding los yog pouring, tusyees faib cov compound hla lub valve disc nto los tsim ib lub cev ntsuab. Tuav lub thickness ntawm 2-5 hli, kom ntseeg tau tias nyob ib ncig ntawm cov npoo ntawm lub disc.

3.3 Kev kho mob

Lub cev ntsuab yog muab tso rau hauv ib lub autoclave thiab rhuab nrog chav lossis cua kub (150-180 ° C, siab> 700 psi, rau 1-4 teev).

Cov txheej txheem kho cov kab sib txuas thiab kho cov EPDM, tshuaj lom neeg thiab kev sib txuas rau cov tub ntxhais hlau los ua ib qho seamless, ib-thooj hauv ob sab phlu. Ua kom kub maj mam kom tsis txhob muaj cua npuas lossis tawg.

3.4 Machining tiav

Tom qab txias, txiav cov npoo sab hauv thiab sab nrauv siv lub tshuab dhos CNC los xyuas kom meej tias cov disc thiab lub rooj zaum haum zoo kawg nkaus (siab ± 0.05 hli). Tshem tawm cov roj hmab ntau dhau thiab tshuaj xyuas cov ntug profile (Ni-Cu txheej yog xaiv tau rau kev txhim kho hnav tsis kam).

3.5 Kev Tshuaj Xyuas Zoo thiab Kev Xeem

ib. Thickness thiab Adhesion Test: Ultrasonic thickness ntsuas (tsawg kawg 2 hli); Tensile Test (peel quab yuam> 10 N / cm).

b. Kev Ntsuam Xyuas Kev Ua Haujlwm: Npuas Tight Seal Test (API 598 tus qauv); Kev Ntsuas Siab / Nqus Tsev (PN10-16, tsis zoo siab tsis kam).

c. Chemical/Aging Test: Immersion nyob rau hauv cov kua qaub thiab alkaline xov xwm, xyuas expansion <5%; Kub-kub laus (120 ° C, 72h).

4. Daim ntawv qhia kev xaiv

PTFE hauv ob sab phlu yog haum rau cov xov xwm corrosive heev (xws li cov kua qaub, alkalis, thiab cov kuab tshuaj), thaum EPDM hauv ob sab phlu yog haum rau dej-raws li, me me media (xws li dej thiab dilute acids). Ua ntej cov tshuaj sib raug zoo, qhov kub thiab txias, siab, thiab tus nqi txhawm rau txhim kho daim ntawv thov. Zhongfa Valve tsim cov kab npauj npaim li qub nrog wafer, flange, thiab lug xaiv. Thov hu rau peb nrog cov lus nug.

Post lub sij hawm: Oct-28-2025